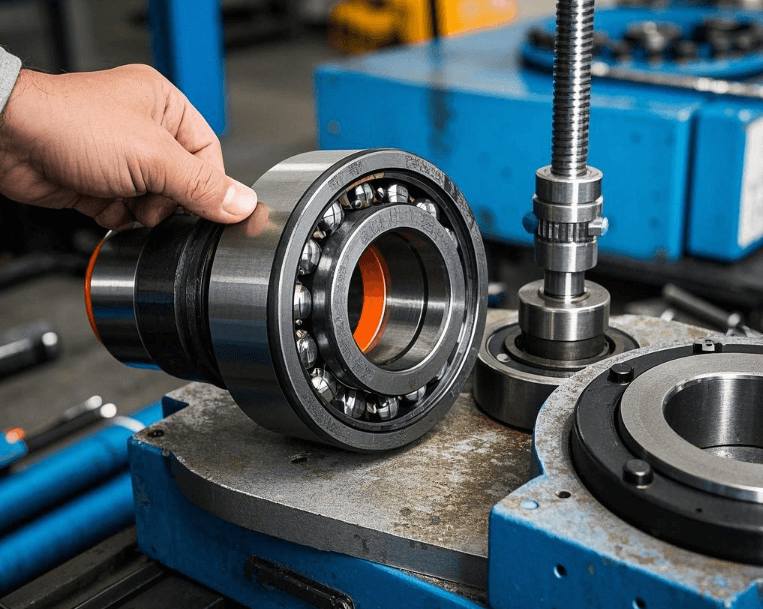

How to correctly disassemble and install bearings?Rolling bearing clearance, refers to one of the rings in a fixed state, another ring along the radial or axial direction can produce the maximum range of activities, can be divided into radial clearance and axial clearance of these two categories. In the rolling bearing assembly, the size of the clearance control is critical, neither too large, nor too small. Once the clearance is too large, at the same time to bear the load of the number of rolling body will be reduced, a single rolling body to withstand the corresponding increase in the load, which will not only lead to the bearing of the rotary precision decline, will also shorten its service life.

Disassemble and install bearings be very careful.

When the clearance is too small, the friction will increase, which will lead to an increase in heat, aggravate the wear and tear of the components, and also shorten the service life of the bearings. Therefore, when assembling bearings, the clearance must be strictly controlled and adjusted. The so-called preload, is in the assembly process, to the inner ring or outer ring of the bearing to apply an axial force, so as to eliminate the clearance, so that the rolling body and the inner and outer rings of the contact parts of the initial deformation. Preloading can improve the rigidity and rotational accuracy of the bearing in working condition. For those bearings that are subjected to large loads and have high requirements for rotational accuracy, they are usually operated without clearance or with only a small amount of interference, which requires preload adjustment during assembly. Adjustment of clearance and preload is generally achieved by appropriate axial displacement of the inner and outer rings of the bearing.

Disassemble and install bearings be very careful.

Before proceeding with the mounting of the bearings, it is important to clean the bearings, journals and housing holes. Installation process, the use of special tools will be bearing smooth, even pressure into, do not use a hammer and other hard objects directly hit the bearing. If there is no special tool, it should be padded with a copper rod or a wooden rod before hammering, to ensure that the pressure can be evenly distributed in the inner ring and outer ring of the bearing, to prevent unidirectional pressure, to avoid tilting of the bearing, damage to the surface of the fit or resulting in the installation of the eccentricity of the situation.

During the mounting of the bearing, if the fit of the bearing with the journal and the housing hole is found to be too tight or too loose, the mounting must be stopped immediately and a suitable bearing must be selected for mounting. If there is any deviation in the journal or housing hole, it should be repaired before installation.

After installation, start the machine, measure the temperature of the bearing housing, and listen to the sound it makes. If the temperature is too high, the clearance is too small; if the sound is abnormal, the clearance is probably too large. Based on the results of the inspection, adjust the clearance after stopping the machine.

When dismantling the bearings, pay particular attention to the fact that pressure should not be transmitted through the rolling elements, so as not to damage the cage of the bearings. The bearing should be dismantled as slowly as possible using a puller. If you do not have a puller, you can also put a copper rod or a wooden rod on the pad and gently hammer to dismantle the bearing, and at the same time be careful not to damage the surface of the journal or the bearing housing hole.